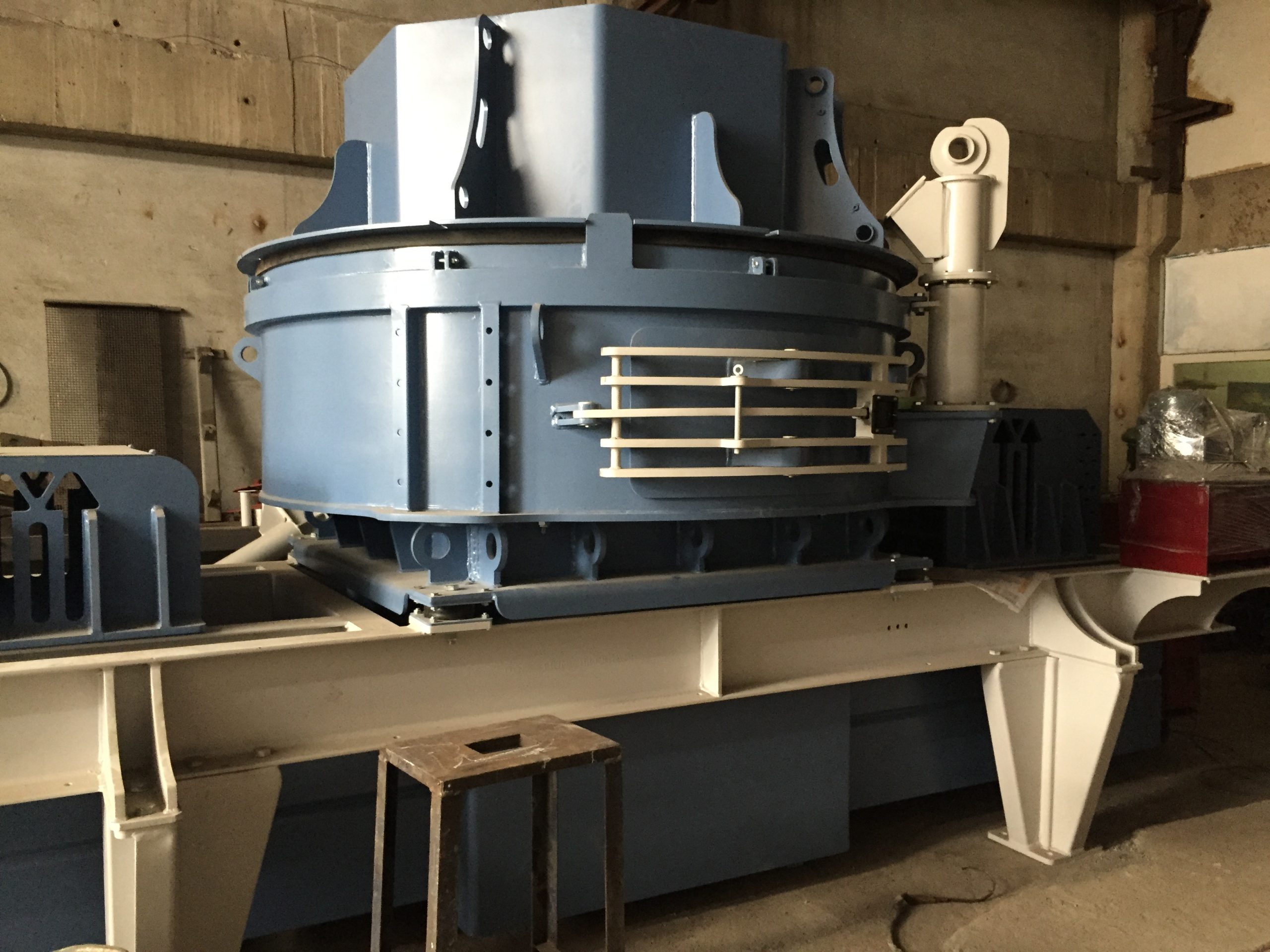

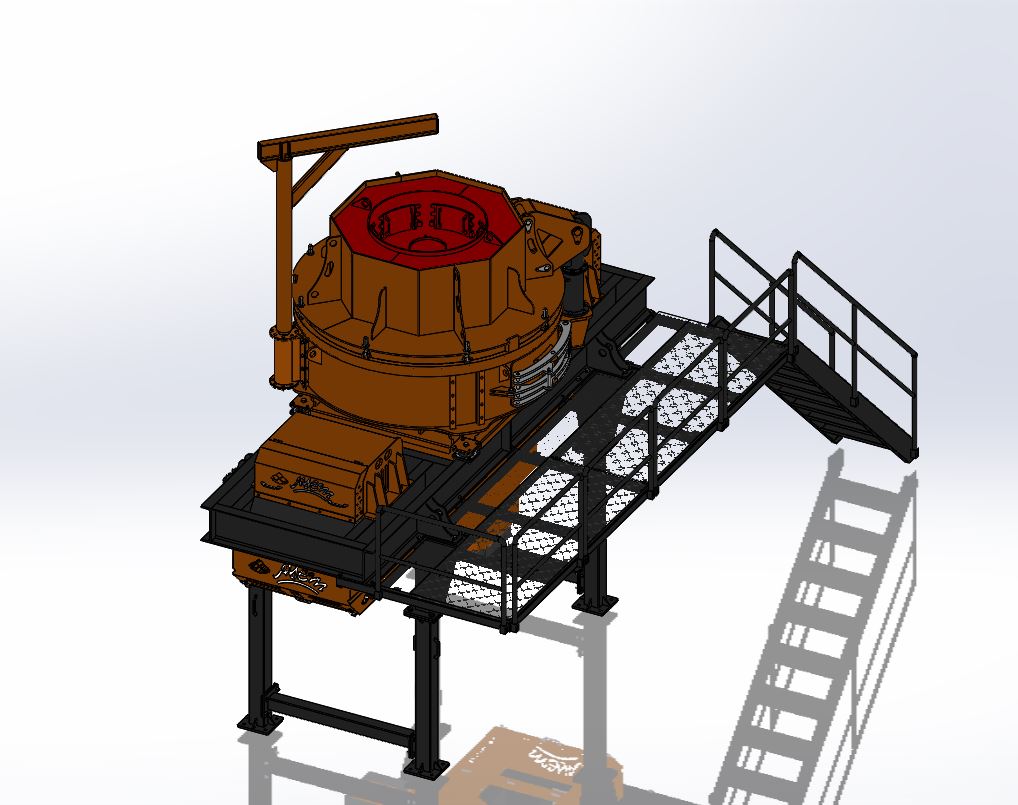

Vertical Shaft Crushers

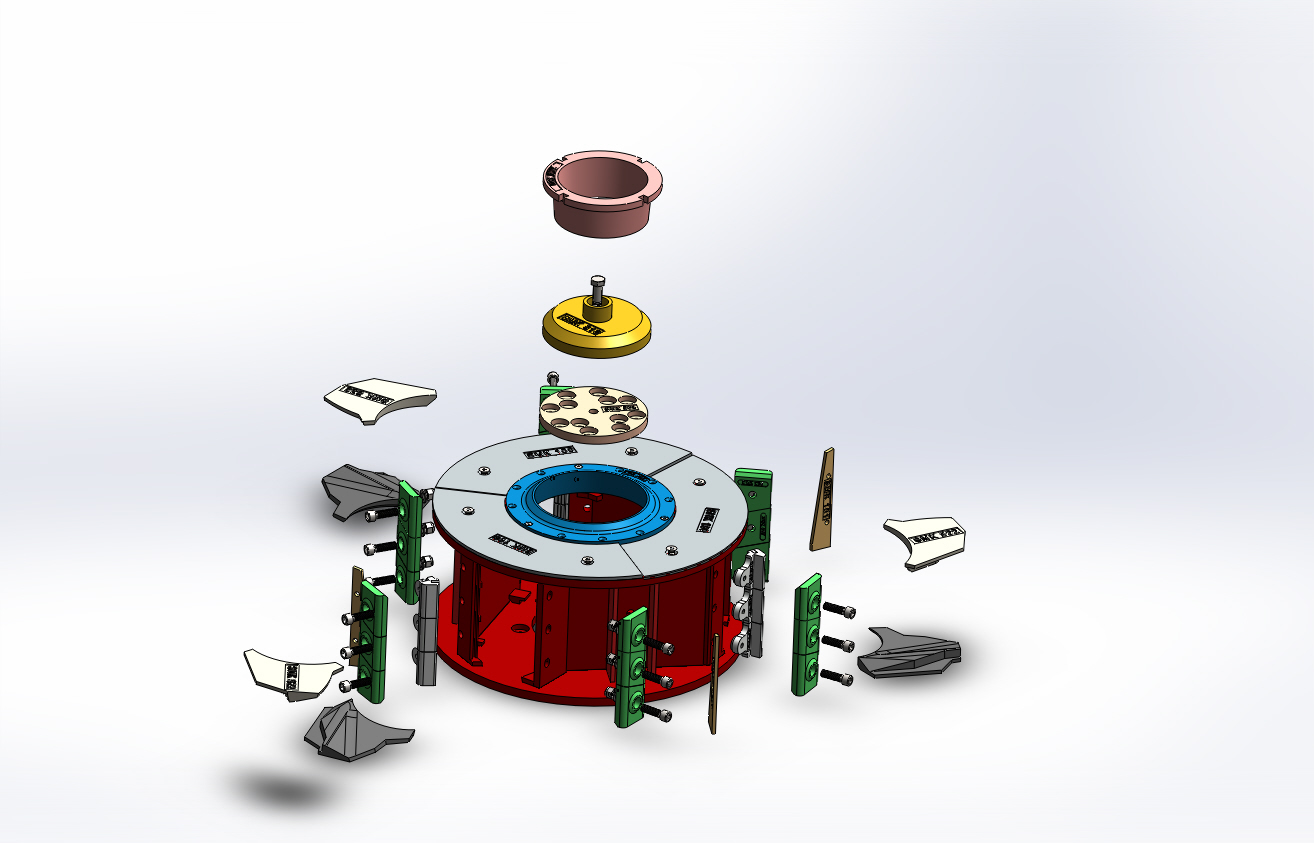

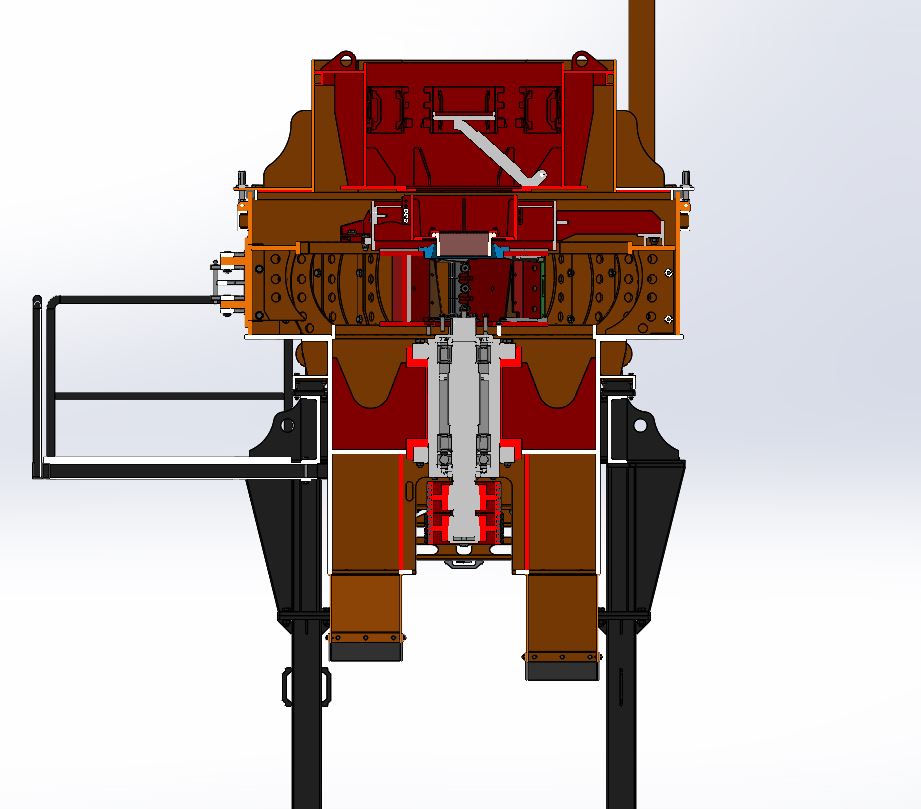

Vertical shaft crushers are classified under two subheadings: open rotor and closed rotor. Vertical Shaft Impact Crushers are crushers with high sand ratio and cubicity ratio, used to obtain 0.5 sand and gravel by crushing all kinds of medium-sized, hard, abrasive materials.

In Vertical Shaft Crushers, the crushing process takes place by throwing the material fed by the crusher’s feeding chamber to the stone lining in the crushing chamber at high speed through the rotor rotating at high speed. Feeding the crusher: Since the crusher performs the crushing process by hitting stone against stone, spare parts consumption is quite economical.

USAGE AREAS OF VERTICAL SHAFT BREAKERS

Vertical Shaft Impact Crushers are used to break natural stones in stream materials,

In the crushing process of cement material by reducing the size of the materials to be processed in the mill and maximizing the ratio of smaller sized materials,

In case cubic material is required in Limestone, Basalt and Dolomite quarries,

In the production of sand, gravel and gravel to be used in concrete and asphalt production,

In the production of materials including fine-grained products used in road infrastructures,

Vertical Shaft Crushers are used to reduce the size of coke added to liquid steel by spraying to increase the carbon content.

Explanation

| MODEL | RATED SIZE (mm x mm) | ENGINE (kw/dev-dak) | ROTOR SPEED (m/s) | MAX WAIT (mm) | CAPACITY (ton-hour) | WEIGHT |

| AYM-VSI-1000-OR | 01000-4 | 2×200-1500 2×250-1500 | 50-70 m/s | 100 | 300-350 | 19500 |

| AYM-VSI-900-CR | 0900-3 | 2×200-1500 2×250-1500 | 50-70 m/s | 45 | 250-300 300-350 | 13250 |

| AYM-VSI-800-CR | 0900-2 | 250-1500 315-1500 | 50-70 m/s | 40 | 200-250 220-270 | 11250 |

| AYM-VSI-700-CR | 0700-2 | 200 – 1500 | 50-70 m/s | 30 | 120-150 | 9800 |

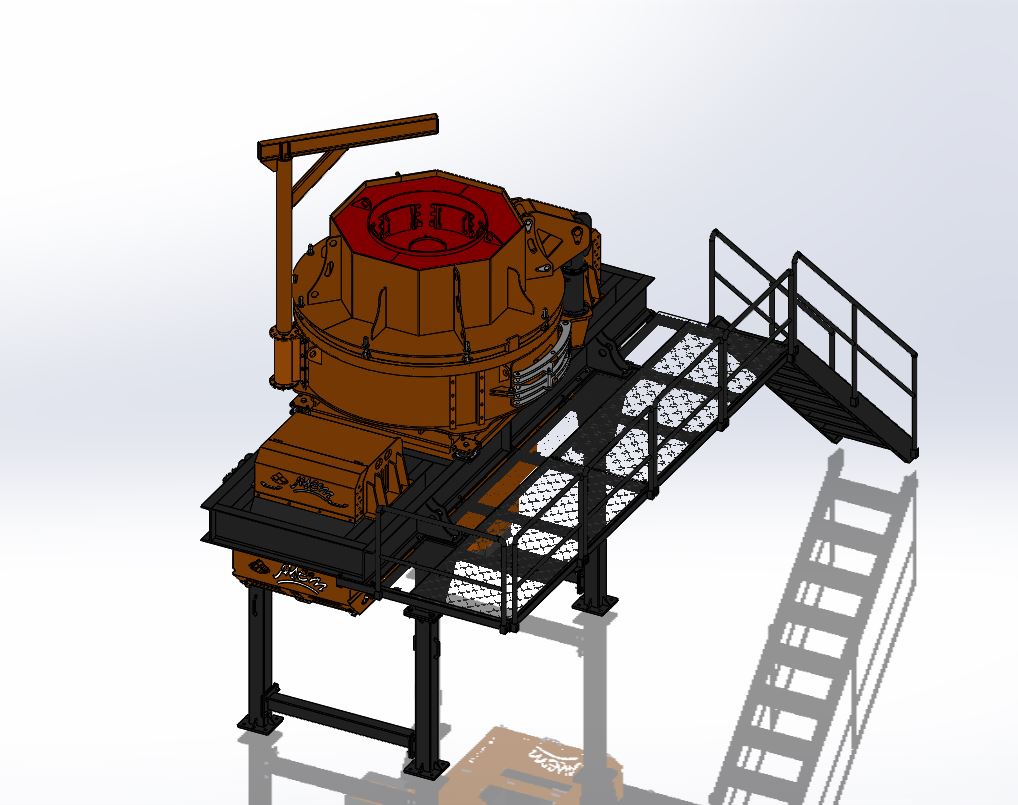

Gallery