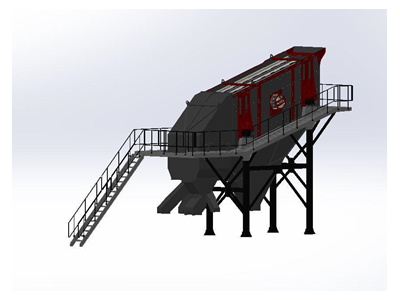

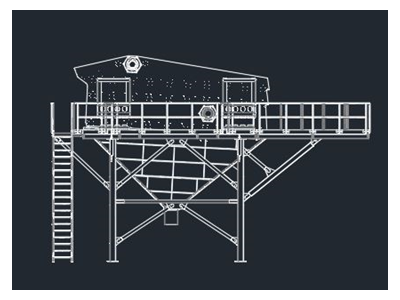

SCREENS

Graduated Sieve

Chassis parts and chute parts of vibrating screens may vary depending on the usage area and space availability. If washing is to be done in the facility, the washing installation is mounted on the sieve with a very simple installation by passing installation pipes through the holes on the standard sieve body. You can contact us for the latest technology vibrating screen.

Dewatering Screen

It is used when river sand and limestone stones are desired to be washed to 250 microns. Polyurethane sieving surface with 3 degree reverse angle greatly reduces the water in the material. It works together with the hydrocyclone and sludge pump, ensuring maximum separation of fine material from water and producing clean material.

Horizontal Vest

Horizontal sieves provide the highest quality sieving compared to other types of sieves. The grain size measurements of the materials sieved in horizontal sieves give the closest value to the desired final size measurements. Eccentric weights are adjustable. They are linear vibrating screens. It is a high efficiency screen model using 8 bearings in the drive system.