CRUSHERS

Primary Impact Crushers

Primary Impact Crushers; They are rotor crushers with a very high reduction and cubic ratio, working with high capacity on materials of medium hardness and low silica content.Primary Impact Crushers are used in crushing large sized stones thanks to their special alloy pallets and crushing plates.

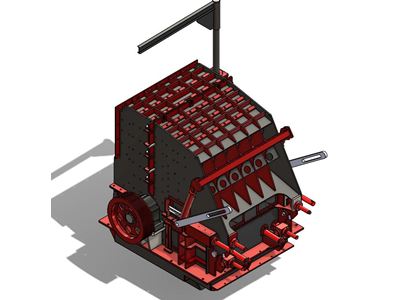

Primary Jaw Crusher

Jaw Crushers; They are primary and secondary crushers designed to crush all kinds of materials, regardless of their hardness and abrasiveness. Jaw Crushers are jaw crushers that crush the material by compressing and bursting it between the fixed and movable jaws through the elliptical movement of the movable jaw.

Secondary Impact Crusher

Secondary Impact Crushers; They are impact crushers that can perform primary, secondary and tertiary crushing operations, thanks to their three-stage crusher pendulums. Secondary Impact Crushers have versatile usage areas. Secondary Impact Crusher; While they are used as primary and secondary for high hardness materials, they are used as primary, secondary and tertiary for medium and low hardness materials.

Tertiary Crushers

Tertiary Crushers; It is used as a secondary crusher in medium hard materials to obtain 0-5 mm sand. In the working system of Tertiary Crushers; The crushing process takes place by the rotor rotating double-sided at high speed hitting the material against the pendulums. Thanks to the hydraulically adjustable outlet opening, products of the desired size can be obtained.

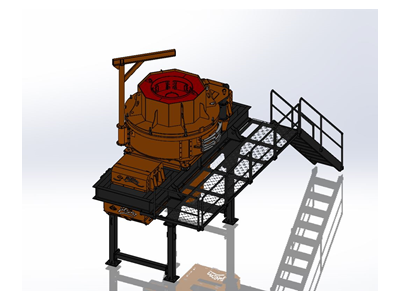

Vertical Shaft Crushers

In Vertical Shaft Crushers, the crushing process takes place by throwing the material fed by the crusher’s feeding chamber to the stone lining in the crushing chamber at high speed through the rotor rotating at high speed. Feeding the crusher: Since the crusher performs the crushing process by hitting stone against stone, spare parts consumption is quite economical.

Pdk01

Take a detailed look at the product coded Pdk01 in the Breakers category.